This post has been reproduced from our AtomicLimits blog. The Spatial ALD day started with a introduction to the topic by ALDAcademy, followed by mainly contributed company talks. See original version of the blogpost here.

At the start of summer we hosted the first Spatial ALD day at the Eindhoven University of Technology. In this blogpost, I want to look back at this day with a few highlights. Also, you can find photos and downloadable presentations at the end of this post! The Spatial ALD day was also covered in the latest edition of the NEVAC journal (Dutch Vacuum Society, or Nederlandse Vacuüm maatschappij). The article is in Dutch, you can download this issue for free here.

The Spatial ALD day

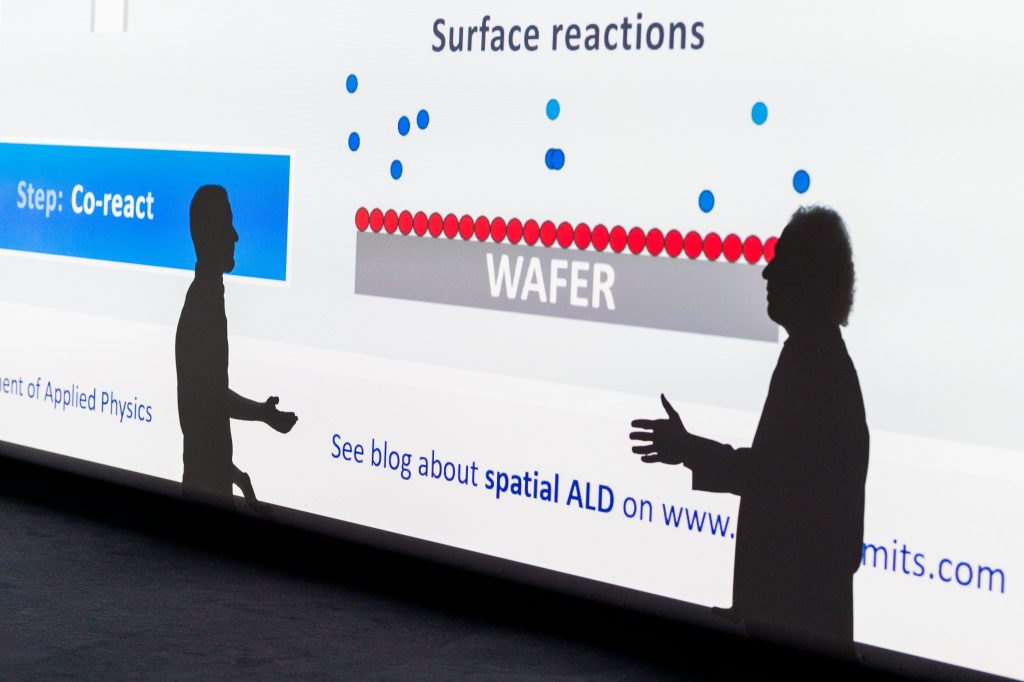

This day was inspired by and part of our spatial ALD research project, funded by NWO. See also our earlier blogpost on this project and registration page for the event. The aim of this day was to bring together people, companies and knowledge institutes that are involved with or interested in spatial ALD. Although I might be a bit biased, based on the very positive feedback I have the feeling we really succeeded in this! The day covered various aspects: In the early morning, there was a more tutorial-like session on basics of (spatial) ALD by the ALDAcademy, followed by invited presentations from academia as well as many companies contributions. We ended the day with a lab tour at the Plasma & Materials Processing group of TU/e and closing drinks.

Some facts and figures

- Almost 70 participants, 1/4th international (mostly: Germany, Finland & France)

- A nice 60/40 mix of academia and industry

- 10 company presentations, 2 invited talks from academia and a morning session by the ALDAcademy

Things that stood out

Here I would like to highlight a few high-level things that stood out, based on our own impressions but also from the attendees (special thanks to Erik Langereis). Any insights you want to share? Feel free to leave a comment at the bottom of the page!

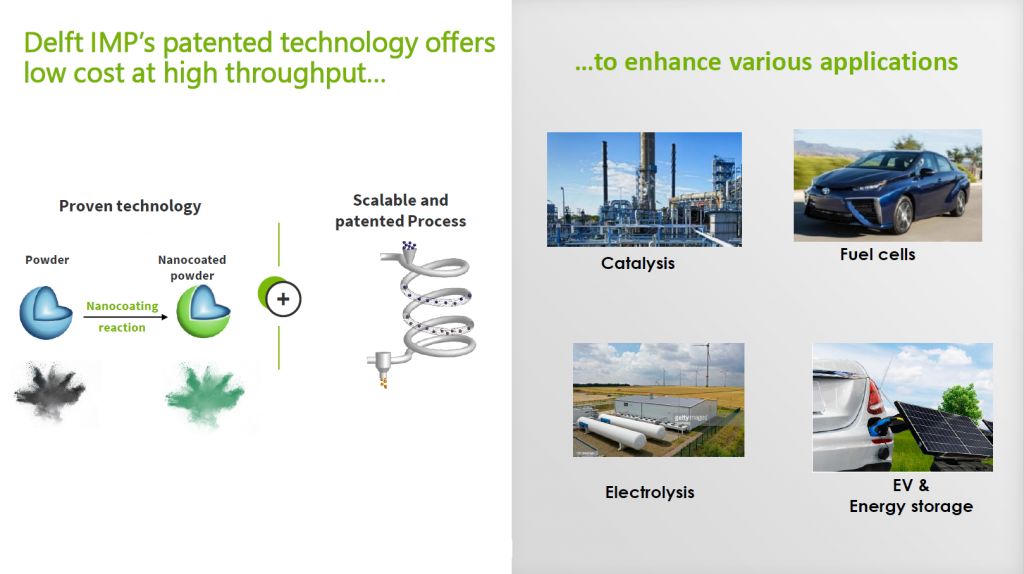

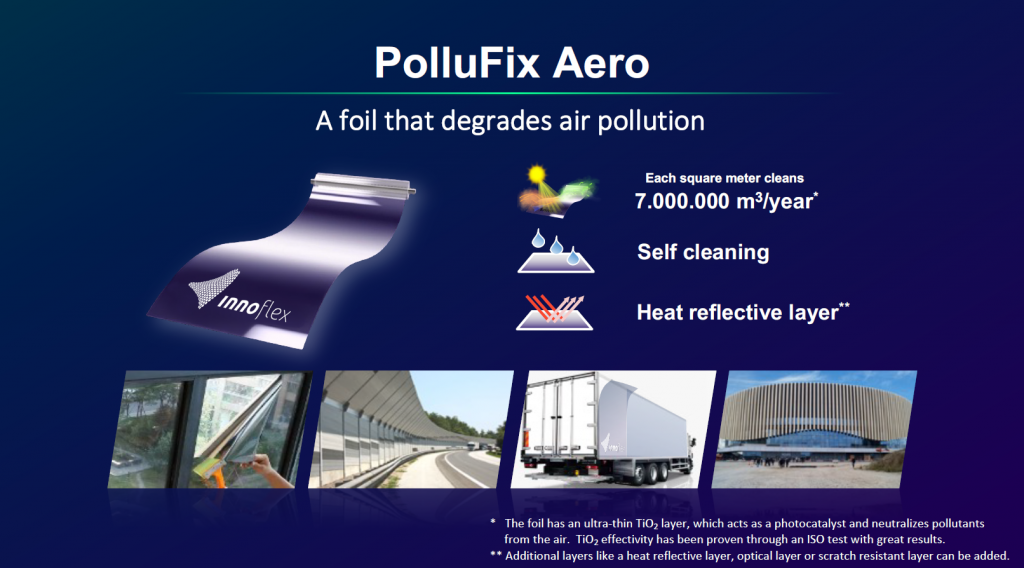

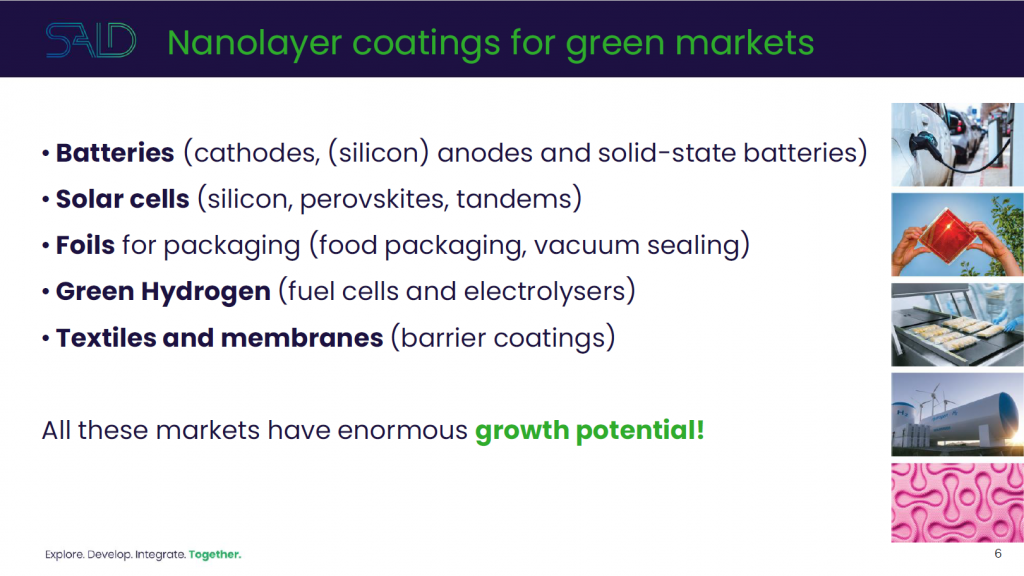

Sustainability as big topic for spatial ALD: It appears that companies increasingly see sustainable applications as a viable market for spatial ALD, as can also be seen from a few slides shown below that I selected from the company presentations. Many of the company presentations discuss the potential in e.g. batteries, solar cells, fuel cells, electrolysers, etc. Two companies even recently “changed face” to emphasize this change of focus: SoLayTec started sister company SALD, SALDTech changed into SparkNano. Also sustainability of precursors is a topic of interest, especially since most spatial ALD applications target very high surface areas, hence a high precursor consumption. As was nicely pointed out by Nils Boysen of RU Bochum, it is not abnormal to waste 100 grams of chemicals to synthesize 10 grams of precursor. Also because of this, precursor recycling is an important topic! This is pursued by e.g. SparkNano, which will be addressed further in an upcoming interview that will be posted on this blog.

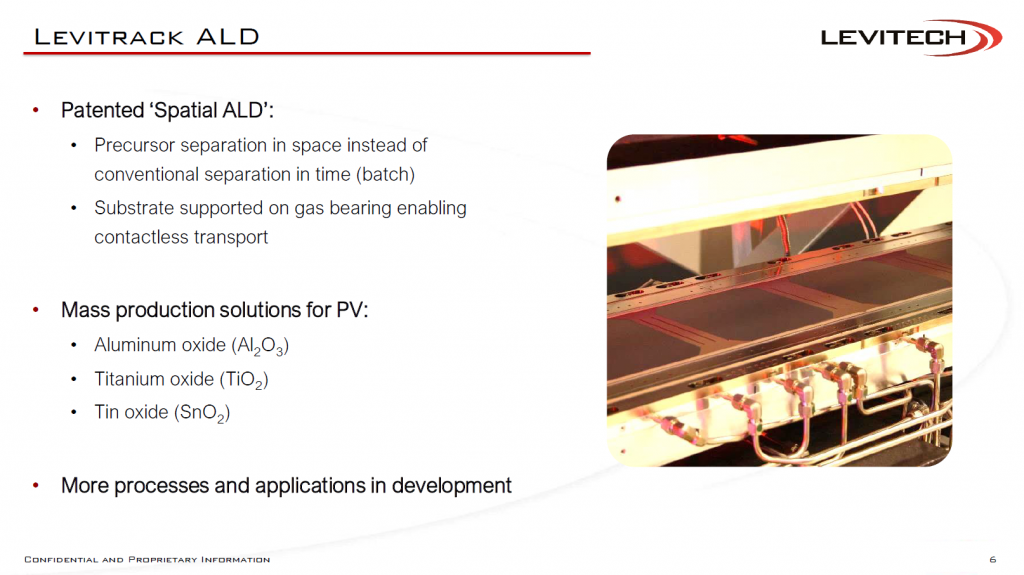

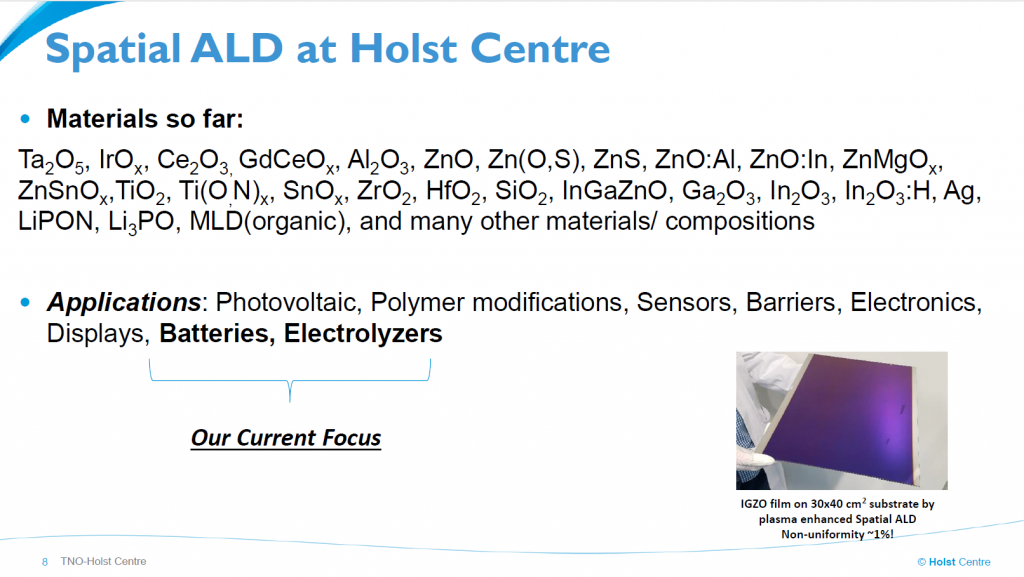

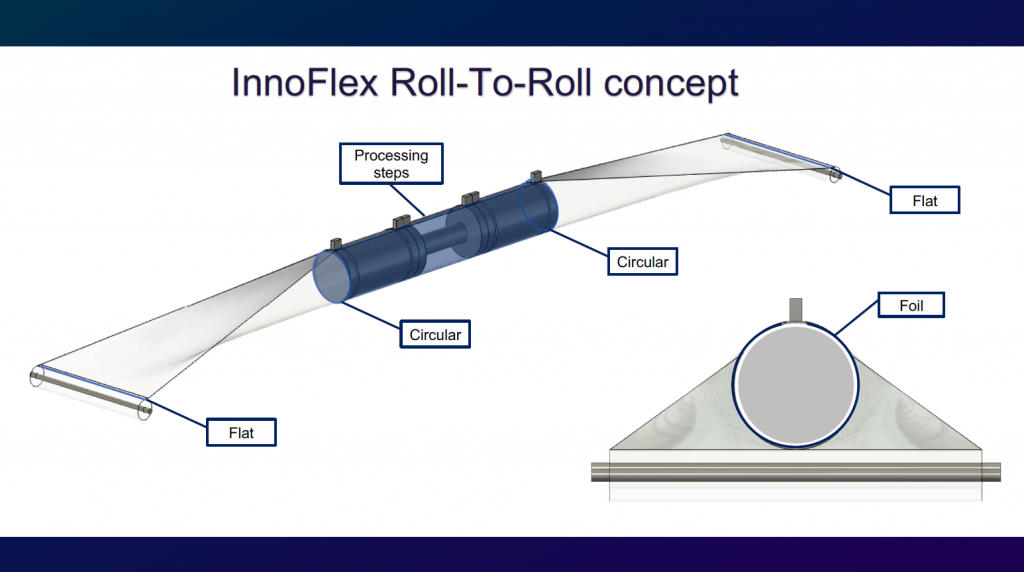

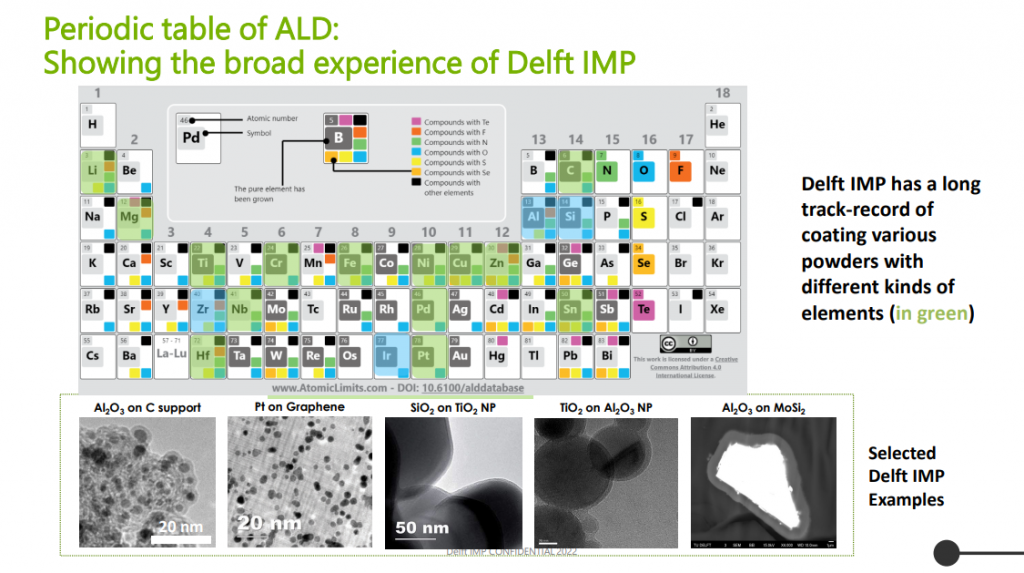

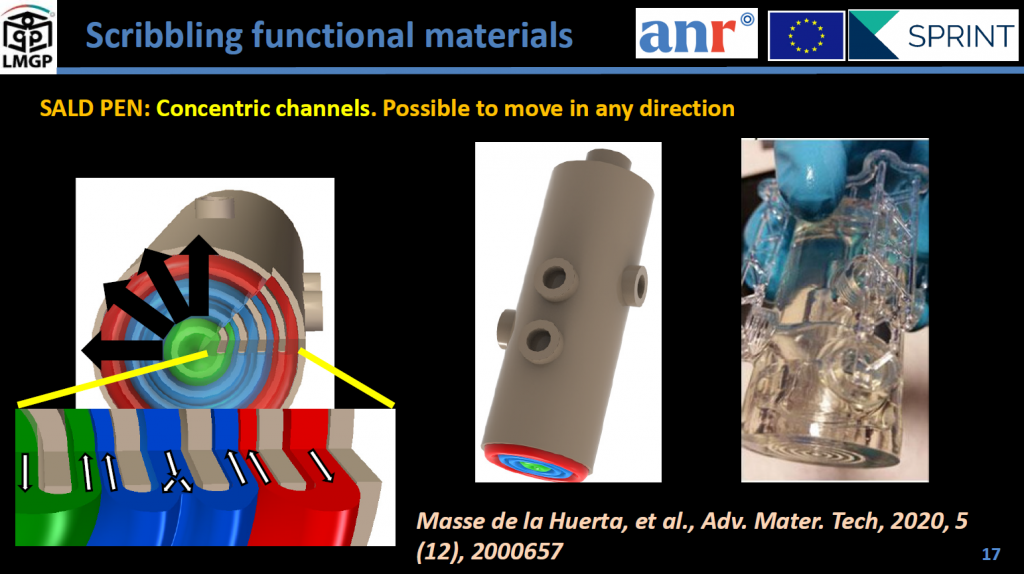

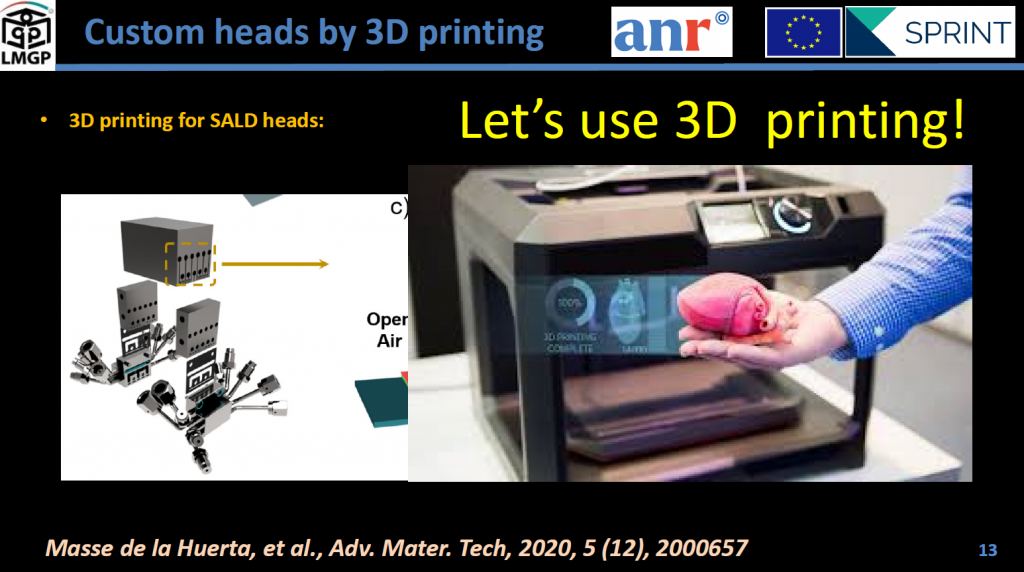

Many (more) innovations in hardware design: Spatial ALD comes already in many configurations. Systems exist for the deposition on wafers, on (glass) sheets and also on flexible foils. This translates to (multi-unit) modular systems in which one substrate is coated per deposition unit (e.g., systems by SALD, SparkNano), linear systems through which many substrates move in a row (e.g., system by Levitech) and rotating systems in which multiple substrates are positioned on a carousel and rotate through the different injection zones (e.g. Beneq). For roll-to-roll systems (e.g. Beneq, SparkNano and Smit Thermal Solutions), Innoflex presented a new concept that facilitates flexible foil handling. Next there is also the option to use plasmas during the spatial ALD process. Plasma ALD is key in the Beneq rotary system (as optical coatings are rather thick) but it is also key in SparkNano’s approach while SALD is working on it as well. Delft IMP is spearheading spatial ALD on particles through a clever design which provides a continuous process without purge steps and in which reaction products accumulate over the cycles. Next there are approaches to use spatial ALD locally on a substrate. David Muñoz-Rojas of Grenoble-INP/CNRS presented their work on a so-called “SALD pen” and also linked this with other efforts at the TU/e (see paper and movie) and by Atlant 3D.

Challenges for scale-up to high-volume manufacturing: spatial ALD has already proven itself in high-volume manufacturing (HVM) in the solar cell industry for the deposition of Al2O3 nanolayers for backside passivation of PERC solar cells (see also earlier blogs one, two). Throughputs of 5000+ wafers per hour have been reported. Levitech reported that they also have HVM processes for TiO2 and SnO2 now, two materials that also find their application in photovoltaics, especially for silicon solar cells and their tandems with perovskite solar cells. One important aspect that was addressed here is the ability to avoid backside deposition, something which is not trivial for a conformal deposition process such as ALD (especially not at HVM throughputs). Obviously scaling up to HVM brings many challenges. With their system to coat particles/powder, Delft IMP addressed several issues that they are currently facing when developing their 100+ kg/hr system: the enormous surface-to-volume ratios, the needed control, the consumption of N2 and heat, high-volume precursor handling and powder handling, and cleaning of the system. It was discussed that N2 recirculation is probably required. As mentioned before, SparkNano also discussed precursor recycling.

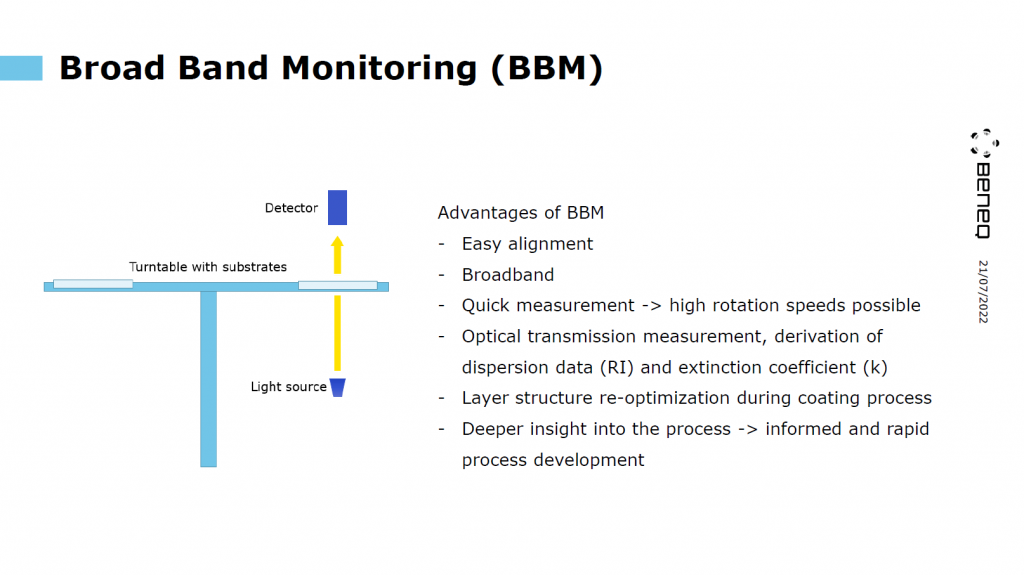

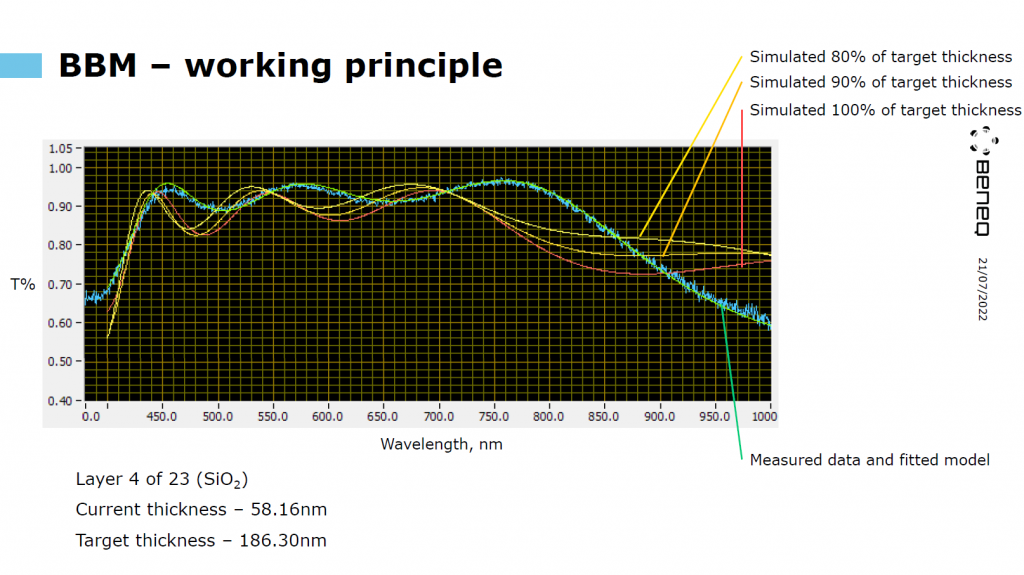

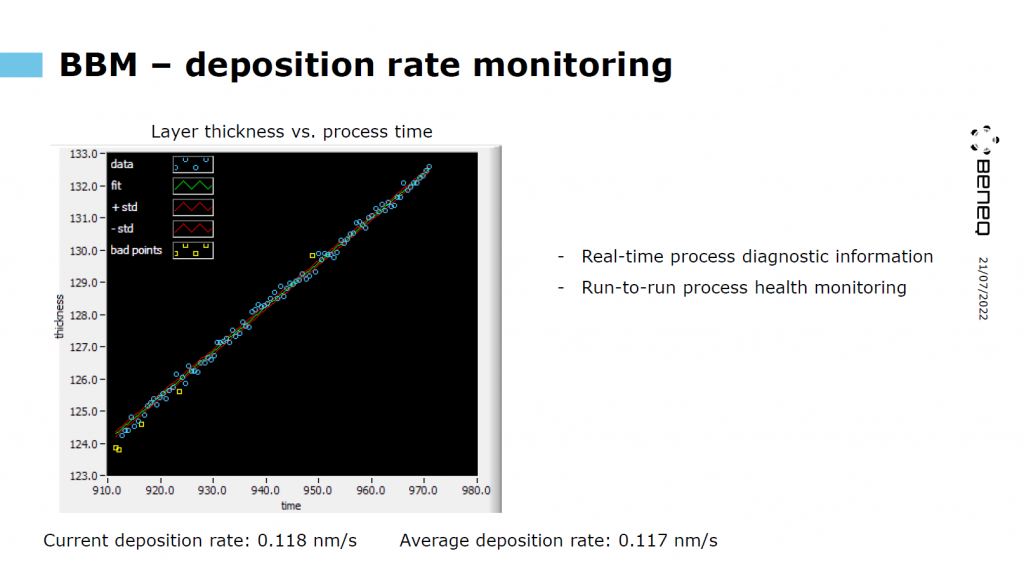

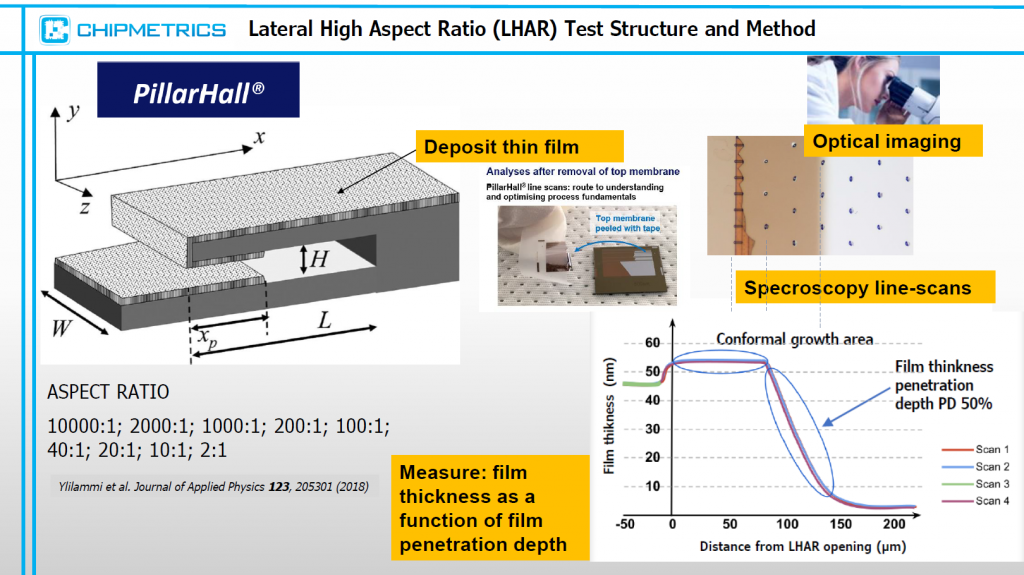

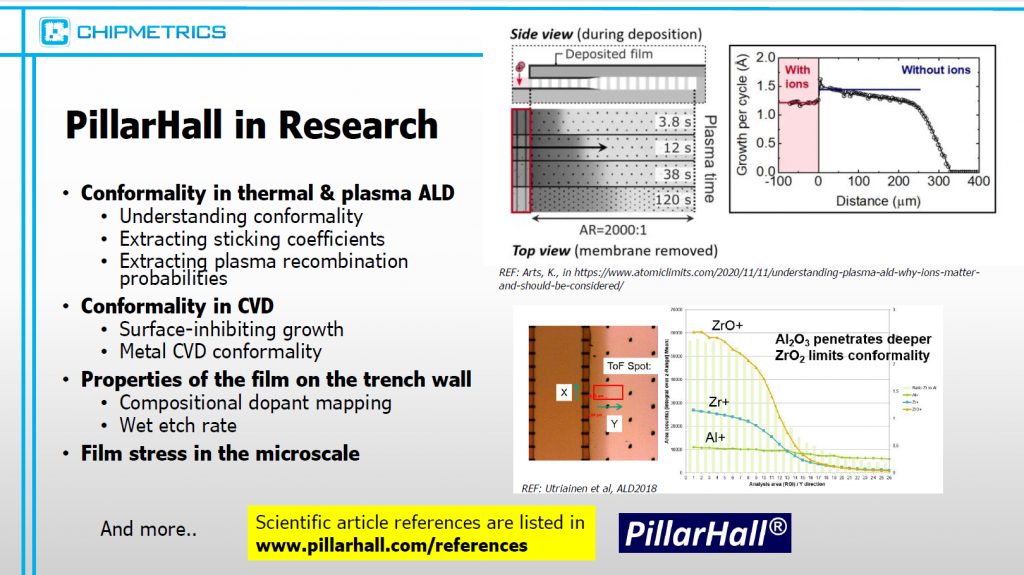

(In-situ) process metrology and process control: This topic also came back multiple times. The clearest example is the presentation by Chipmetrics, which was devoted to their PillarHall test structures. See also our earlier blog. In a nutshell, these are test chips with lateral trenches that allow for easy (optical) evaluation of conformality, which can tell you a lot about your ALD process. Beneq on the other hand showed an optical method (broad band monitoring, BBM) for in-situ monitoring of the thickness of their optical coatings prepared in a rotary spatial ALD reactor. For optical coatings such metrology is very important and the big advantage of having this capability in-situ is that it allows the process to be (re)optimized as it runs.

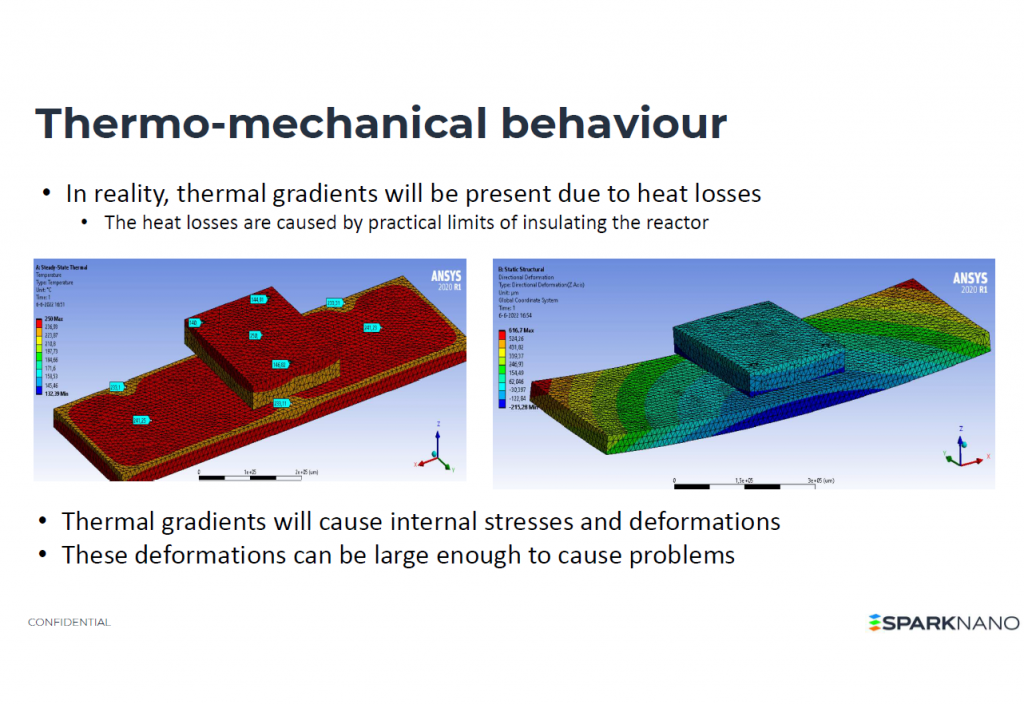

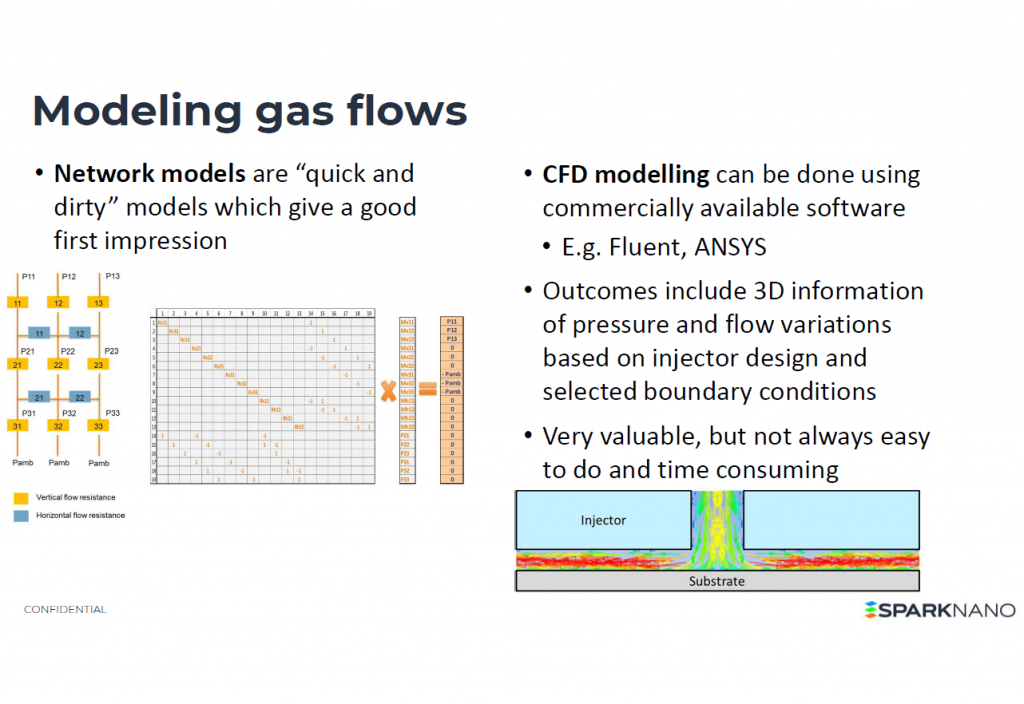

ALD systems provides many interesting challenges for system architects: What struck me is that there are so many aspects and expertises that come into play in the field of spatial ALD. Materials science, precursor synthesis, flow dynamics, plasma physics, tool design, … In this respect I really enjoyed the presentation of SparkNano on design challenges and solutions for spatial ALD equipment, where Systems Architect Jeroen Smeltink showed examples of how modeling of thermal expansion as well as gas flows play a key role in design. He also discussed the importance of materials choice, particularly when plasmas are used. Spatial ALD with plasmas require special ceramics but also grounding is extremely important. Furthermore, it was interesting to hear about the use of 3D printing of stainless steel to fabricate deposition heads (by the company SALD) and also David Muñoz-Rojas elaborated about the opportunities provided by 3D printing for hardware.

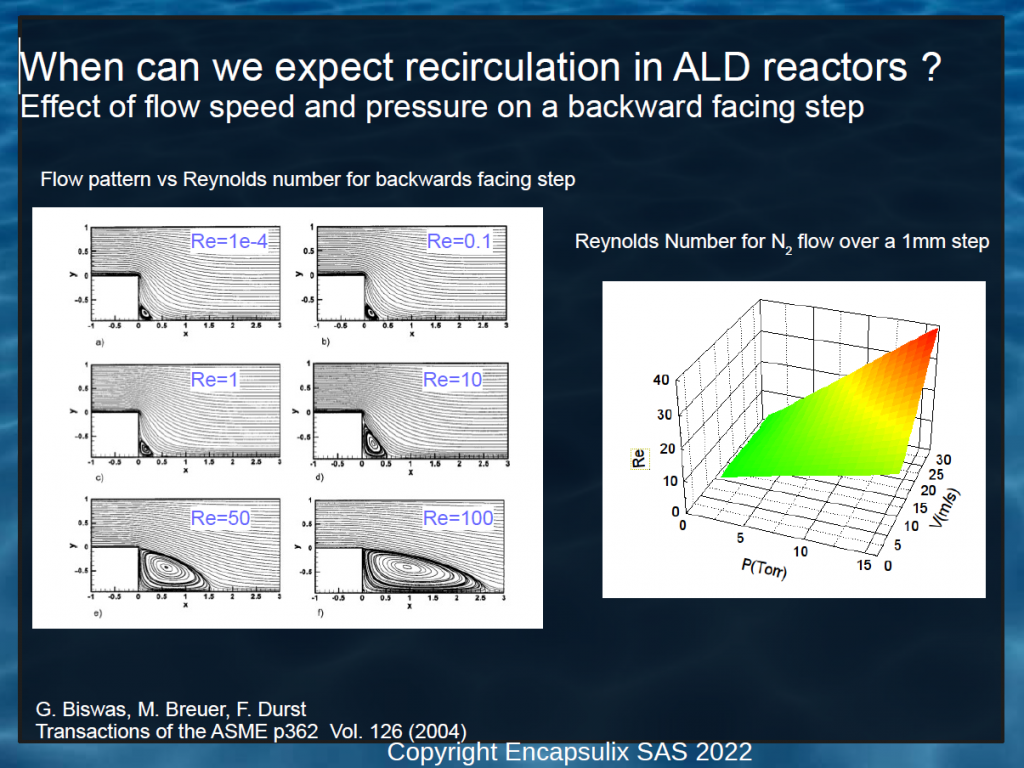

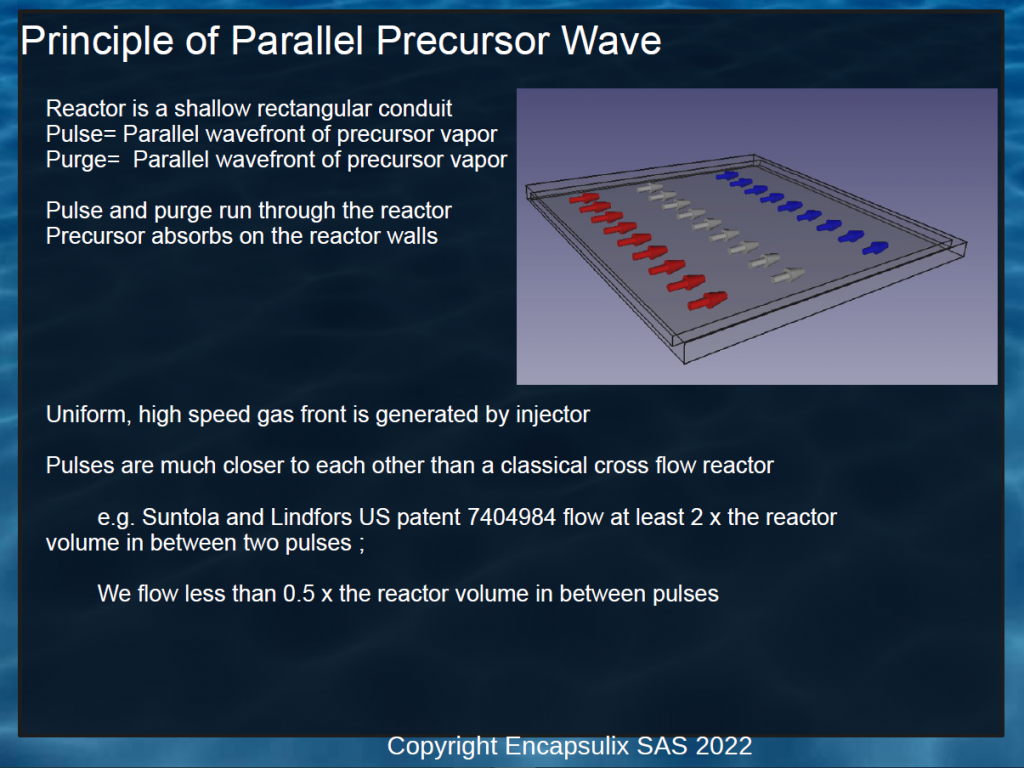

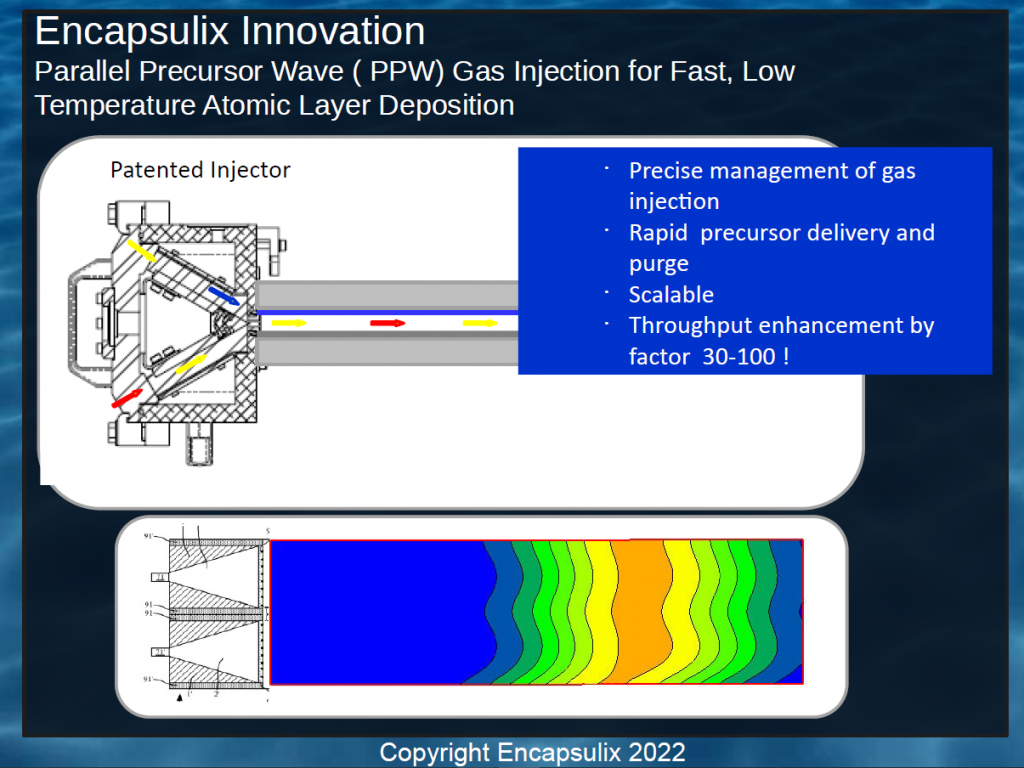

You don’t have to go spatial to go fast! While the day was of course about spatial ALD, the last presentation by Jacques Kools of Encapsulix showed that you can also achieve high deposition rates in temporal ALD using so-called parallel precursor wave ALD. In a nutshell, in this approach you have a constant laminar flow of nitrogen through the reactor in which you inject pulses of precursor and water with very short purge times in between (order of 100 ms!). The trick here is clever (aerodynamic) reactor design that prevents recirculation vortices in the gas flow, while also choosing a gas flow that is not too high (which creates vortices, high Reynolds number) nor too low (then the precursor pulses widen due to diffusion).

Pictures

Downloadable presentations

- Grenoble INP – Spatial ALD research at LMGP (David Muñoz-Rojas)

- RU Bochum – Precursor Chemistry for Spatial ALD (Nils Boysen)

- Beneq – Spatial ALD at Beneq (Philipp Maydannik)

- Chipmetrics – PillarHall Lateral High Aspect Ratio Structures (Mikko Utriainen)

- SALD – Spatial ALD at SALD (Erik Kremers)

- Delft IMP – Large-scale continuous coating of powders to enhance materials (René Hauser)

E-mail to request slides: info@delft-imp.nl - SparkNano – Design challenges and solutions for spatial ALD equipment (Jeroen Smeltink)

- InnoFlex – InnoFlex rolls in a different way (Kevin Lagarde)

- Levitech – Levitrack ALD for Perovskite tandem solar cell manufacturing (Mark Steltenpool)

- TNO – Spatial ALD for Energy Applications (Paul Poodt)

- Encapsulix – Parallel Precursor Wave ALD: Minimizing the purge times of temporal ALD (Jacques Kools)

Finally, a big thanks to Jeanne Loonen for helping with the organization, Twycer for the great photos and NWO for funding!